![]() Distribution

Distribution ![]() News

News ![]() Notes & Interesting Articles

Notes & Interesting Articles ![]() Products

Products ![]() Pricing

Pricing ![]() Quality Assurance

Quality Assurance

Celestron Overview And History

Celestron is a telescope manufacturing company whose name remains synonymous among the astronomical community with compact and versatile Schmidt-Cassegrain telescopes (SCT's). A Celestron Schmidt-Cassegrain telescope (SCT) was often the first astronomical instrument that a budding astronomer experienced at their High School or college, and these are still commonly found in use at government and industrial research applications as well as in a neighbor's back yard. Celestron's U.S.A. made and imported products earned the well-deserved reputation of providing affordable value. The good reputation of Celestron was gained through their more than forty years of experience and success in innovative product design most notably of their Schmidt-Cassegrain telescopes, by new innovations and continual product improvement, and their customer service. One can not underestimate the impact those pioneers at Celestron made in changing the marketplace for amateur astronomy. Celestron instruments made it possible for many amateurs to become enthralled by the hobby, and many of the now famous names in astrophotography (and many others unpublished) were able to capture amazing images and earn recognition for their accomplishments and discoveries.

Above: Celestron Pacific company logo of the 1970's.

It incorporates the Schmidt-Cassegrain optics set with distinctive aspheric corrector lens, and light path.

The company was founded by Tom Johnson in the late 1950's as Valor Electronics to manufacture electronic components for the aerospace market. The movement from electronics to telescopes was prompted by Tom's interest in making a six inch reflecting telescope, but one that might be more compact and suitable for his two young sons. At first a hobby, this developed into a business that underwent several transformations before what we recognize as Celestron emerged.

The company was founded by Tom Johnson in the late 1950's as Valor Electronics to manufacture electronic components for the aerospace market. The movement from electronics to telescopes was prompted by Tom's interest in making a six inch reflecting telescope, but one that might be more compact and suitable for his two young sons. At first a hobby, this developed into a business that underwent several transformations before what we recognize as Celestron emerged.

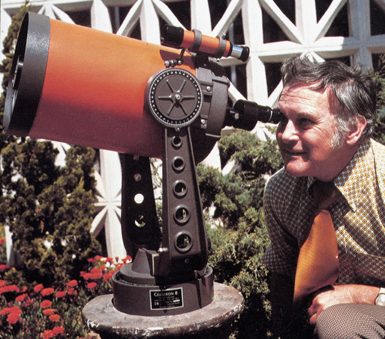

Right: Tom Johnson with an original $795 Celestron C-8 telescope of the early 1970's with the original orange tube finish*. Mr. Johnson founded Celestron and was the optical genius behind the development of the the technique to cost effectively mass produce the Schmidt-Cassegrain telescope Corrector Lens. This image appeared in Celestron literature but reversed left to right (154,993 Bytes).

* The original three coat five step process paint applied by Celestron to the orange tubes is not longer made, being discontinued due to its high lead content.

Click on image to see enlarged view (259,058 bytes)

When in 1970 Alan Hale had come on board to manage the corporate affairs of the company. And in 1970 they introduced the first high quality mass-produced portable SCT the "Celestron C-8", Celestron became the world's first and for a long time the most respected manufacturer of these versatile astronomical instruments for amateurs. This in spite of the fact that through the 1960's Celestron had built SCT's of up to 22 inch aperture for government and industrial clients. By 1971 their offerings from 2430 Amsler Street in Torrance, California included the Celestron 5, Celestron 8, the 5-1/2 inch aperture f/1.65 Schmidt-Camera, and observatory telescope models on a pier mount: Celestron 10, Celestron 12, Celestron 16, and Celestron 22. Several of the telescopes were sold without fork mount for uses including ultra-telephoto lens. In 1971 the first C-14 telescopes complete with a sand cast fork and base were produced.

The move and increased in offerings by 1975 had Celestron offering products made in their factory at 2835 Columbia Street, Torrance, California. The standard production telescopes offered now included the C-5, C-8, C-14, and the 5-1/2, 8 inch (200mm) f/1.5), and 14 inch (355mm) f/1.7 Schmidt Cameras. The offerings included visual accessories (Finders, Eyepieces, Diagonals, etc.) imported from Vixen of Japan. Photographic accessories included the Celestron-Williams Cold Camera (35mm format, and a 120mm model for the C-14!), Piggyback Mounts for photo guide telescopes, Off-Axis Guiders, and much more. The C-14 would continue to reign for decades as the largest production catadioptic telescopes, and even today this remains the largest aperture practical portable telescope optical tube assembly made. By 1980 Celestron International employed more than 100 people, while Tom Johnson retired from day to day work at the company helping out as needed on a consulting basis. Celestron also had a factor sales representative working in Chicago and in New York City to call upon local retailers, and handle matters within their region.

All the Celestron fork mounted telescopes of the time were driven by a synchronous AC powered motor. In order to facilitate operation in the field from 12 volts DC sources and to provide users with the capability to precisely correct tracking for astrophotography when operating on AC or DC current, Celestron sourced Drive Correctors from local electronics manufacturers. One of these was among the first products made under the "AccuTrak™" trademark by "Gieseler Electronics". Founded by Tim Gieseler in Santa Cruz, CA this went on to become Orion Telescopes, the largest and most successful mail order oriented reseller of amateur telescopes. In later years when Davionix, Accutrak and other drive corrector makers discontinued production the owners of the older C-14 mounts were left scrambling for drawings from which to repair old Celestron Heavy Duty or third party drive correctors, or changing from their fork to a German Equatorial Mount.

Swiss Owned In 1980 Tom Johnson and Alan Hale sold Celestron Pacific to Diethelm Keller Holding, a large family owned manufacturing concern based in Zurich, Switzerland. This change appeared transparent to Celestron's customers as Diethelm did not interfere too often with Celestron operations.

Swiss Owned In 1980 Tom Johnson and Alan Hale sold Celestron Pacific to Diethelm Keller Holding, a large family owned manufacturing concern based in Zurich, Switzerland. This change appeared transparent to Celestron's customers as Diethelm did not interfere too often with Celestron operations.

This was a good time to sell a telescope making company since right around the corner was Comet Halley whose known appearance in 1985 would send telescope sales into the stratosphere well into 1986. By 1980 the Celestron product line added the C-11 telescope to the product line replacing the long discontinued C-10. While the telescopes were offered as optical tubes or on 120 volt powered fork mounts, the C-14 included a DC powered Declination motor necessitating a Drive Corrector with matching output. The C-11 and C-14 (50 lb. OTA with 58 lb. fork) shared the same massive 26 lb. equatorial wedge and 33 lb. locked angle Field Tripod.

Right: Celestron company headquarters and factory building at 2835 Columbia Street (47,311 bytes).

Click on image to see enlarged view (181,134 bytes).

Anticipating Comet Halley The opportunities and the excitement of the 1980's prompted Celestron to develop several new products and alliances. Much of these revolved around the anticipated visit of Comet Halley, among the brightest of the periodic comets. Comet Halley becomes visible from Earth every 75 or 76 years, and so the community anticipated being able to see it from 1985 into 1986.

While the better products continued to be marketed under the Celestron trademark an increasing selection of less costly smaller telescopes (with narrower 0.965" diameter focusers and eyepieces) were purchased from overseas and sold through Celestron bearing the "Cometron" trademark. Cometron was attempt to better distinguish their better telescopes from those oriented to the novice or impulse buyer. Early on, most of these telescopes were reasonably well made even if Company Seven preferred to offer larger and more capable telescopes that were more likely to draw someone into our hobby and keep them in the hobby using the telescope. Most of the imported models were achromatic refracting telescopes of 60mm to 80mm aperture, and 4-1/2" to 6" aperture Newtonian style reflecting telescopes. These were well engineered products made by Vixen of Japan, with the telescope tubes provided on either a alt-azimuth or German equatorial mount including the Polaris model. But these offerings also included the superb and lightweight Vixen doublet fluorite apochromatic 70mm to 102mm aperture refracting telescopes, with optics similar to the lenses sold in the then unrivaled Takahashi FC series Apo telescopes. Interestingly, many amateurs not only found their first introduction to serious amateur astronomy through Celestron's catadioptric telescopes, but many if the few who first came to appreciate what a fine refractor could reveal did so at the eyepiece of a Celestron/Vixen fluorite Apo!

Among the new telescopes made with the coming Comet Halley in mind was the handy 5.5 inch aperture f3.64 compact Comet Catcher" announced in 1983. This is a closed tube Schmidt-Newtonian arrangement with a compact 19 inch overall length. Comet Catcher was built incorporating a sliding focuser of 1.25 inch diameter made by Vixen of Japan, this was the same focuser provided with the Vixen made Newtonian reflecting telescopes. With the included Celestron 18mm Ortho eyepiece the Comet Catcher operated at 28x showing a field of view of 1.6 degrees wide but was capable of fields of view as wide as 3.4 degrees with optional eyepieces. All things considered, including its price, this was one of the few comparatively economical telescopes developed specifically with Comet Halley in mind that had the wide field of view combined with the light gathering power to see it well.

Celestron's marketing efforts gradually penetrated beyond the specialty telescope stores and into department stores venues. While the better products continued to be marketed under the Celestron trademark, an increasing selection of less costly smaller telescopes with narrower 0.965" diameter focusers and eyepieces, were purchased from overseas and sold through Celestron bearing the "Cometron" trademark. Cometron was attempt to better distinguish their better telescopes from those oriented to the novice or impulse buyer. Early on, most of these telescopes were reasonably well made even if Company Seven preferred to offer larger and more capable telescopes that were more likely to draw someone into our hobby and keep them in the hobby using the telescope. Most of the imported models were achromatic refracting telescopes of 60mm to 80mm aperture, and 4-1/2" to 6" aperture Newtonian style reflecting telescopes. These were well engineered products made by Vixen of Japan, with the telescope tubes provided on either a alt-azimuth or German equatorial mount including the Polaris model. But these offerings also included the superb and lightweight Vixen doublet fluorite apochromatic 70mm to 102mm aperture refracting telescopes, with optics similar to the lenses sold in the then unrivaled Takahashi FC series Apo telescopes. Interestingly, many amateurs not only found their first introduction to serious amateur astronomy through Celestron's catadioptric telescopes, but many if the few who first came to appreciate what a fine refractor could reveal did so at the eyepiece of a Celestron/Vixen fluorite Apo!

In 1984 Celestron instituted the cosmetic change in 1984 from orange to black painted optical tubes for their SCT's. Starbright® protected silver mirror coatings were introduced; then changed to enhanced aluminum alloy coatings after a high number of silver coatings tarnished within a few years after production. Several new telescopes including the first radical design change in years of the Celestron fork mounts introducing the "Super C-8" Series. The SPC-8 telescope incorporated improved bearings, and drive worm and wheel gear sets made by the Edward R. Byers Co. of Barstow, California. These gear sets provided improved tracking performance so when the telescope was equipped with an optional Drive Corrector it would be easier to take good astrophotographs. Celestron introduced an economical hybrid Celestron C-8 with the optical tube assembly sold on the "Super Polaris" German equatorial mount made by Vixen; the first pairing of an SCT with the German Mount. The first somewhat mass-produced computer controlled 'go-to' telescope, the "Compustar 14" was announced then, a very heavy system compared to the standard C-14, Compustar was designed for permanent installation such as in an observatory. Almost every conceivable visual and astrophotographic accessory was available from Celestron, many of these made by Vixen of Japan.

Celestron's marketing efforts were among the factors that left it in an unsteady condition after Comet Halley passed. We attended a large gathering of Celestron retailers at Torrance in 1984 where new products were announced and the future of the hobby was discussed. Many of the retailers owners did not even know how to Pole Align a telescope; we viewed this as an ominous sign for the future of specialty shops. A Celestron sales manager pointed to a graph indicating Celestron's history of telescope sales, with the growth plotted through 1986 and with what we thought was a flawed prediction that sales would do nothing but climb from year to year. Part of Celestron's efforts to increase sales involved special deals that were negotiated with the larger retailers and to mail order oriented camera stores. Celestron offered extended payment terms that encouraged the larger retailers to stock up, but that left Celestron waiting for payments some of which would come late if ever. And among the special terms were liberal return policies so that no matter how many telescopes a camera or department store bought they would be able to return anything that was not sold. So 1984 saw every "Tom, Dick, and Harry" outfit trying to get into the telescope business, many of these resellers could not explain through which end of the telescope one should look!

The astronomy magazines became flooded with new advertisers. The small specialty telescope store ads like those by Company Seven and of Roger Tuthill "The Astronomers Friend" became dwarfed those of the New York mail order camera stores who purchased pages at a time in each publication and who competed on all they were able to do - price. So as they had virtually destroyed the local camera markets in many cities, these volume and discount oriented shops 47th Street Photo, Adorama, etc. began to take a toll on yet another specialty market. When the owners of several telescope stores complained about this to the magazines, the magazines had no reason to care since they were raking in unprecedented advertising revenue. When the owner of Company Seven asked Lester Stockman the advertising manager of Sky & Telescope to consider setting standards that would ban pages solely of price listings in favor of something more like those in the more classy magazines National Geographic and Scientific American for example, Stockman replied "we do not edit advertisers copy". At that Company Seven replied that we would no longer support Sky & Telescope with our advertising revenue - and since then Company Seven has not paid a penny in advertising in any form to either of the astronomy magazines. And since then the number of specialty telescope stores in the country began the downward spiral.

The the major challenge for telescope makers was how to make enough of all these new telescopes and make them well enough to suit the demand? Unfortunately, the pace of production and hiring outpaced the associated learning curve and most of the big guys (including Celestron) did not deliver their best products over this period. We started to experience increasing incidences of missing parts, poor packaging and shipping damage, and variations in the qualities of the optics. So this is the period when Company Seven began its own in house quality assurance programs, and this is among the aspects of our services that to this day sets Company Seven apart from other resellers. By 1985 Celestron quality control had so diminished that Company Seven failed more C-8's than we passed. And while the heretofore dominant Celestron spun, Meade Instruments was growing and getting their act together with better quality control and new competing products too with LX3 series of telescopes included.

Well soon after Comet Halley the chickens came home to nest. The market had became saturated by telescopes as anyone who was a likely buyer for the next several years used the passing of Comet Halley as their reason to jump in then. So after the comet passed not only did sales dip, they dipped to well below what the sales had been before 1983. Furthermore, so many telescope were built and on dealers shelves that Celestron and most large makers of telescopes found themselves in the position of taking in unprecedented returns of unsold inventory (remember those special deals?), and chasing companies that owed them money.

By January of 1987 Alan Hale was asked to return Celestron to manage its recovery. Among his first decisions was to invite the owners of Celestron's most competent retailers including Company Seven, and Roger Tuthill, to visit Celestron in February to review and critique the product line. Many good suggestions came from this meeting, and some personnel changes at Celestron followed. Among the suggestions were the mention by the late Roger Tuthill that Celestron's larger telescope Fork Mounts should incorporate carrying handles suitable even when the user is wearing gloves; this simple idea solved the routine problem of fingers getting pinched between the OTA and Fork Mount. Since then Celestron and even competing telescopes incorporated carrying handles. Some who attended had the opportunity to meet Tom Johnson again and talk optics (see below) and other hobbies.

By January of 1987 Alan Hale was asked to return Celestron to manage its recovery. Among his first decisions was to invite the owners of Celestron's most competent retailers including Company Seven, and Roger Tuthill, to visit Celestron in February to review and critique the product line. Many good suggestions came from this meeting, and some personnel changes at Celestron followed. Among the suggestions were the mention by the late Roger Tuthill that Celestron's larger telescope Fork Mounts should incorporate carrying handles suitable even when the user is wearing gloves; this simple idea solved the routine problem of fingers getting pinched between the OTA and Fork Mount. Since then Celestron and even competing telescopes incorporated carrying handles. Some who attended had the opportunity to meet Tom Johnson again and talk optics (see below) and other hobbies.

Founders of Celestron: Tom Johnson (left), the original full owner and optics design and manufacturing Guru of the outfit. And Alan Hale (right), the President and business brains of the outfit. Both hosting Celestron's conference of selected retailers held in February 1987 at Celestron.

Founders of Celestron: Tom Johnson (left), the original full owner and optics design and manufacturing Guru of the outfit. And Alan Hale (right), the President and business brains of the outfit. Both hosting Celestron's conference of selected retailers held in February 1987 at Celestron.

In 1987 Celestron production numbers were reduced while the quality was improved. Some of the production cuts were ordered by Alan Hale to allow production technique improvements to be instituted, while some reductions were simply due to waning demand as the post Comet Halley industry-wide hangover revealed the market was saturated. Through the 1990's the company cooperated with other companies to develop new products, those companies had excellent reputations for customer service and satisfaction including: Losmandy Hollywood General Machining who offering some of the most refined precision equatorial mountings and accessories available, and Santa Barbara Instruments Group the proven innovators of CCD camera technology, and Software Bisque who then were leaders in CCD planetarium, telescope and CCD camera control software.

Efforts by Celestron to take in the comments of the meeting in 1987 produced what are fundamentally two of the best engineered 8 inch SCT made in the 20th centruy: the Ultima 8 and the Utima 8 PEC. These reliable telescopes featured comparatively massive Fork Mounts incorporating large bearings and a precision Byers worm gear drive set. The Ultima 8 base housed two cylindrical rechargeable lead acid batteries; this was a product first offered by Roger Tuthill as a retrofit for older telescopes. These telescopes had the capability to operate off external 12 volts DC sources, a wonderfully rigid and easy to adjust Equatorial Wedge. And yes, it had carrying handles on the Fork Tines and hand control knobs that could be operated even when wearing gloves. The provided 50mm Finder and the hard shell but light weight carrying case are still missed by us who recall these telescopes. The Ultima 8 PEC followed with some improvements, including the capability to operate off an internal 9 volt battery that is easy to find in stores, but not changed as easily as we'd like in a cold dark night.

Celestron introduced "PEC" (Periodic Error Correction) circuitry with the Ultima 8 PEC telescope. These telescopes could be programmed by the user before starting to take astrophotos with an easy 4 minute recording cycle, this dramatically reduced the amplitude of periodic errors that occur when a telescope relies on a worm gear set for tracking. This meant the telescopes could take better images without spending the costs associated with larger and heaver precision worm gear and wheel sets. In a Sky & Telescope review of 8" Schmidt-Cassegrains, it was noted, "the Ultima 8's drive error was the least I have ever seen in a mass-market telescope." Astronomy Magazine said of the drive, "a textbook straight line" and "the PEC is impressive. It worked better than advertised." PEC would soon be offered in some third party Drive Correctors, while Meade and others would follow this path opened by Celestron.

Developments included new telescopes including the CG-11 in 1992, the first successful commercial mating of a high performance Losmandy G-11 German Equatorial Mount with the C-11 optical tube. In 1996 Celestron released the first new Schmidt-Cassegrain telescope in decades - the Ultima 9-1/4, an f/10 telescope on a fork mount but one whose optical prescription differs from its predecessors; it has become regarded as producing the sharpest and most clear images of the Celestron and Meade models in this aperture range.

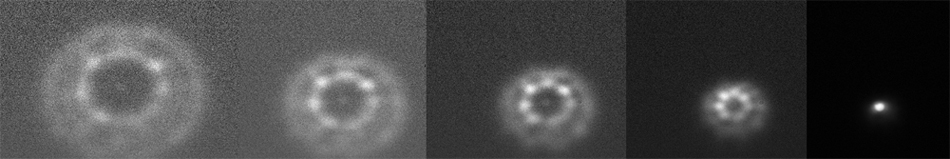

Above: Through focus star test. Images taken by C7 during failed acceptance testing of a new Celestron C-8 telescope S/N 889108 on 10 December 1994.

The image should show distinct, concentric, smooth rings resembling the image at top right. Instead the pattern defocused into a "ring of pearls".

These optics had multiple problems introduced during manufacturing, and yet Celestron shipped it and most retailers (and their intended customer) would have probably never realized this.

Back to Innovating In August 1996 Celestron began shipping the new Ultima 2000, the world's first mass produced computer controlled 8 inch Schmidt-Cassegrain telescope. These were Fastar compatible systems, lightweight and handy to use ("Child's Play") that predated the much heavier Meade LX-200 telescopes by about six years. We found it interesting to see how many Celestron mail order retailers started advertising the telescope "in stock" weeks before the first production model was ever shipped, blindly selling anything new with no scrutiny. However, in keeping with our tradition of being among the last to sell something new Company Seven waited until we felt the new telescope was reasonably well debugged before we started to offer them. And even after their Y2K bug was discovered and resolved we insured all our Ultima 2000 customers were contacted so that we could update their telescope firmware before this service was discontinued some years after later as a critical electronic part was no longer made to allow this work. As simple and lightweight as these telescopes appear, many of the Ultima 2000 telescopes (with and without the Y2K fix) remain providing useful service today even while competing models made a decade or more later have since broken down.

Regardless of the innovations at Celestron, a number of factors were working against it including the introduction and gradual improvement of several new telescopes by their arch competitor Meade Instruments Corp. working from their new large manufacturing facility in Irvine, CA. In the early to mid 1990's Celestron had better quality control and reliability than many of the competing Meade products, and Company Seven even went so far as to drop the Meade product line in part because of this in 1992. Company Seven felt more and more isolated as being the last 'bastion of reason' selling Celestron in the mid-Atlantic region in the face of the Meade advertising onslaught.

The partnerships between Celestron and SBIG led to the July 1997 introduction of the "Fastar" concept; this demonstrated there was innovation still at work in these pioneering companies. Fastar is a CCD imaging accessory made possible because the Secondary Mirror Holder of the Celestar 8 Deluxe and Ultima 2000 telescopes could be removed and interchanged with an optional purpose built lens set and CCD camera holder made to accommodate either of two Celestron CCD cameras or the comparable SBIG ST-5 series CCD cameras. This allowed the f/10 C-8 to operate at f1.95. Fastar produces extremely short exposure times, about 25 times faster than was otherwise possible at prime focus. Covering fields of view with a Fastar 8 telescope as wide as 0.5 x 0.7 degrees, this was the equivalent of shooting the telescope as a 400mm f1.95 lens! The production of Fastar was accompanied by the release of the first CCD cameras sold under the Celestron trademark (made by SBIG) for use with Fastar including the Pixcel 237 and Pixcel 255. The post July 1998 C-14 telescopes were similarly equipped to operate at f2.1, but Fastar became optional later for these and some C-11 models. In time Celestron discontinued the resale of CCD cameras and Fastar customers were referred directly to buy the Pixce 237 as the SBIG ST-237A. Fastar appeared in a time when amateur CCD technology was relatively new, not inexpensive, and these CCD's had small sensor areas - but the Fastar technology made imaging some larger objects more practical. Of course even the Fastar telescopes could accommodate a variety of optional telecompressor lenses at the axial port to vary the effective focal length and f ratio down to f6.3 or as fast as f3.3. By the the following decades the availability of larger format CCD cameras increased, the diminishing availability of compatible new small chip CCD cameras combined with the peculiarities of using Fastar saw the reduction in demand by the turn of the 21st century.

The partnerships between Celestron and SBIG led to the July 1997 introduction of the "Fastar" concept; this demonstrated there was innovation still at work in these pioneering companies. Fastar is a CCD imaging accessory made possible because the Secondary Mirror Holder of the Celestar 8 Deluxe and Ultima 2000 telescopes could be removed and interchanged with an optional purpose built lens set and CCD camera holder made to accommodate either of two Celestron CCD cameras or the comparable SBIG ST-5 series CCD cameras. This allowed the f/10 C-8 to operate at f1.95. Fastar produces extremely short exposure times, about 25 times faster than was otherwise possible at prime focus. Covering fields of view with a Fastar 8 telescope as wide as 0.5 x 0.7 degrees, this was the equivalent of shooting the telescope as a 400mm f1.95 lens! The production of Fastar was accompanied by the release of the first CCD cameras sold under the Celestron trademark (made by SBIG) for use with Fastar including the Pixcel 237 and Pixcel 255. The post July 1998 C-14 telescopes were similarly equipped to operate at f2.1, but Fastar became optional later for these and some C-11 models. In time Celestron discontinued the resale of CCD cameras and Fastar customers were referred directly to buy the Pixce 237 as the SBIG ST-237A. Fastar appeared in a time when amateur CCD technology was relatively new, not inexpensive, and these CCD's had small sensor areas - but the Fastar technology made imaging some larger objects more practical. Of course even the Fastar telescopes could accommodate a variety of optional telecompressor lenses at the axial port to vary the effective focal length and f ratio down to f6.3 or as fast as f3.3. By the the following decades the availability of larger format CCD cameras increased, the diminishing availability of compatible new small chip CCD cameras combined with the peculiarities of using Fastar saw the reduction in demand by the turn of the 21st century.

Above: Celestron Pacific company logo from 1990's into 2006 (22,125 bytes).

Tascoized As Meade came to dominate the 1990's, Celestron sales did not realize improvements and in June 1998 the Swiss owners of Celestron sold Celestron to Tasco Worldwide. Based in Miramar, Florida, Tasco was an importer of department store oriented telescopes. Up to the late 1960's one could argue Tasco offered a reasonable selection in value and performance in their class. However, by the 1990's a Tasco telescope was considered as the poster child of what amateurs should NOT buy, and at Company Seven we viewed this acquisition as Yugo buying General Motors. It was during the Tasco ownership that Celestron was pressed to buy more and more products from Tasco's sources in China; at the time notorious for mediocre quality control much as "Made in Japan" in the 1950's had been no complement. The Tasco 'bean counter' mindset took more and more of a toll on Celestron; we referred to this as the "Tascoization of Celestron". By 2000 Meade was improving its products, Celestron was effectively 'Tascoized, and Meade had taken the lead in sales volume and technology.

Bt 2002 the Meade line had improved its product quality control and terms (allowing us to service Meade telescopes we sold, etc.) well enough that Meade was reinstated at Company Seven. Our predictions about Tasco and Celestron were unfortunately prophetic as the decisions made by the short-sighted management at Tasco finally caused their own collapse in 2002. The Celestron company was again up for sale. As in a prior attempt when Meade and Celestron were in merger discussions, we informed the U.S. Federal Trade Commission that we still believe it is in our communities best interest to have a healthy competition between manufacturers that fosters new products and competitive pricing and as before the FTC implied it would not allow the merger. On 28 June 2002 management employees at Celestron Rick Hedrick, Joe Lupica, and Alan Hale bought Celestron from Tasco operating as "Celestron, LLC" (a limited liability corporation).

In July 2003 Celestron announced a new optional coatings group that would in time pretty much become standard on their better telescopes. If you review the history over the decades then you will see Celestron and Meade have offered competing optional (or later standard) upgraded coatings accompanied by claims of increased light transmission. These could be as simple as the first "Special Coatings" a coating of antireflective durable magnesium fluoride to the Corrector lens of the early Celestron SCT's. Or the first "Starbright" silvered mirrors coating by Celestron, followed by Meade's "MCOG (Multi-Coated Optics Group), followed by reformulations of these by both to do away with unreliable silver coatings of the period. Followed by Meade UHTC (Ultra-high Transmission Coatings) and more recently the Celestron Starbright XLT Coating (extra light transmission). But in fairness to Celestron, their telescopes with the optional StarBright XLT coatings also replace the original standard Soda-Lime float glass material (a greenish tinted glass introducing notable chromatism) from which the corrector lens is made with low iron 'Water White' glass, a more clear and transparent glass instead. Water White glass transmits more light than uncoated Soda Lime glass. Celestron goes on to state "When Water White glass is used in conjunction with StarBright XLT's anti-reflective coatings, the average transmission reaches 97.4% - an 8% improvement!" Of course Meade Instruments followed this by making this standard on their better telescopes too. If one studies the cumulative transmission increases that have been advertised by each subsequent generation of "improved" coating for newer generations over the prior, then we wonder if the latest Celestron and Meade telescopes should be transmitting about 110 per cent of the light coming in?

Above: Celestron's modified company logo from 2006 (12,337 bytes).

Giant Sucking Sound In 1992 the Suzhou Synta Optical Technology Company Ltd. factory was founded in the Suzhou New District, Jiangsu Province, China. Since 1998 it is owned and managed by Mr. Dazhong (David) Shen. It has been among the Chinese based manufacturers prospering initially by cloning American and Japanese ideas and selling them at lower costs to customers in the USA and elsewhere. Their products were distributed under the "SKY-WATCHER" and "ACUTER" brands through distributors, while Synta has sold products in the USA through Celestron and Orion telescopes companies under their trademarks too. By 2000 Synta was developing their own products at their state of the art 280,000 square foot facility, and these included 'go to' technology mounts. As with most Chinese makers, they improved their quality control to be competitive with anyone else in their respective price class, and in some way superior to what we had seen coming from California.

Giant Sucking Sound In 1992 the Suzhou Synta Optical Technology Company Ltd. factory was founded in the Suzhou New District, Jiangsu Province, China. Since 1998 it is owned and managed by Mr. Dazhong (David) Shen. It has been among the Chinese based manufacturers prospering initially by cloning American and Japanese ideas and selling them at lower costs to customers in the USA and elsewhere. Their products were distributed under the "SKY-WATCHER" and "ACUTER" brands through distributors, while Synta has sold products in the USA through Celestron and Orion telescopes companies under their trademarks too. By 2000 Synta was developing their own products at their state of the art 280,000 square foot facility, and these included 'go to' technology mounts. As with most Chinese makers, they improved their quality control to be competitive with anyone else in their respective price class, and in some way superior to what we had seen coming from California.

Right: Flag of the People's Republic of China (8,055 bytes).

It was however some surprise when on 6 April 2005 Celestron CEO Joseph A. Lupica announced Celestron was sold by the management team to SW Technology Corporation, a Delaware based front of Synta Technology Corporation of China. Under the sale terms the prior Chairman Alan Hale and Celestron founder Tom Johnson would remain working for Celestron as consultants. We at Company Seven sensed this was a brilliant choice by Synta since with this acquisition of Celestron they obtained a recognized brand, they now owned American-developed expertise (especially the process to mass produce the aspheric corrector lens), and they owned the two large buildings in Torrance, California. Now they could export the expertise to their Chinese factory, fire the more costly US manufacturing employees, and convert the Celestron factory to warehouse Chinese made goods brought in through the nearby Port of Long Beach. We were flattered to find how accurate our intuition was in when Celestron and later even Meade Instruments eventually closed most meaningful California based manufacturing facilities to send production to Mexico, China and elsewhere. All in keeping with a 1992 prediction by Ross Perot of "that giant sucking sound" of jobs leaving the US. The real fun came in 2008 when Americans burdened by debt, a housing market crisis, and loss of good income paying jobs bucked the trend of increasing their debt and slowed or stopped spending; even the Chinese companies began to realize they can not do well forever if they do not have customers who can buy their products.

But in fairness to Synta, had they not acquired Celestron in 2005 then the Celestron company would probably not be as competitive as it is today since the partnership was simply under-capitalzied to compete with the likes of a publicly traded company like Meade. Nor would Celestron have become able to offer as wide a selection of products and innovation as it does today (for better or for worse). As of 2009 most of the upper level employees have been retained and there were still some manufacturing operations left at Torrance, including the C-14 optical tube assemblies but mounts and most other telescopes are made in China.

But as we think about the ups and downs of both Celestron and Meade, we are mystified at how so many 'educated idiots' and 'bean counters' have been so overpaid to take over a company from knowledgeable founders and then supervise running that company into the ground. Fortunately Synta is a private company that is not yet used to running on the American model, and so in these aspects it has yet another advantage. Since the change of ownership to Synta have observed the quality control of Celestron products become more consistent in the past year or two. And we have also seen improvements to how Celestron responds to our quality control issues.

Celestron telescopes selected for sale by Company Seven generally provide high value in design, innovation, good craftsmanship and reliable service. Precision assembly and meticulous attention to detail by their craftspeople ensured that you could receive the commensurate quality for the money spent. It was these qualities that guarantee hour after hour of comfortable use.

Once obtained, a Celestron instrument that meets Company Seven's standards will become a complete entertainment center and educational resource for you, your family and friends. Purchasing a Celestron translates into pride of ownership and the satisfaction of knowing you have obtained the a good value of optical precision.

Contents Copyright 1994-2009 Company Seven - All Rights Reserved